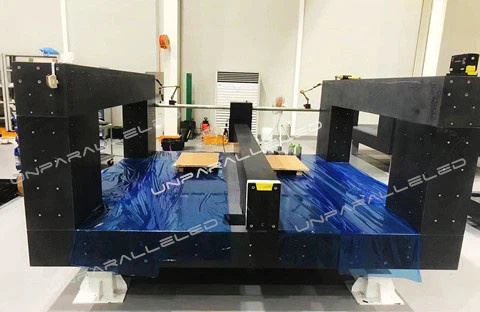

Granite machine components characterized by high precision, such as granite machine beds, bases, gantries, bridges, pillars, and air bearings, offer stable and highly accurate surfaces that ensure the maintenance of precision in machinery during operation.

A growing number of ultraprecision machines-including Coordinate Measuring Machines (CMM) and Video Measuring Machines (VMM)-are increasingly incorporating granite components to replace traditional metal machine beds due to the superior properties of granite. Acknowledging the remarkable qualities of black granite, UNPARALLELED Ltd. specializes in manufacturing precision granite platforms and ultra-precision measurement tools (e.g., precision granite squares and V-blocks). In addition to providing ultra-high-precision standard parts, UNPARALLELED Ltd. also offers large-scale processing services for custom precision granite components.

Granite is an optimal material for applications in precision machinery ranging from coordinate measuring equipment to general machining processes involving honing, grinding, and milling. Depending on specific requirements, various types of granite are available-including Jinan Black Granite and Indian Black Granite.

Our company accepts orders for primary structural components made from granite materials specifically designed for semiconductor-related equipment as well as vision inspection systems and metrology instruments. We specialize in producing extra-large precision granite components; individual pieces can achieve dimensions up to 12000 × 3000 × 1000 mm while the lengths of spliced precision granite products are essentially limitless.

For decades, UNPARALLELED® has focused on manufacturing precision granite, Precision UHPC, precision ceramics, mineral casting, and more. UNPARALLELED® Ultra-high Precision Advanced Manufacturing Solutions specializes in creating custom precision granite components for high-end precision machinery, including CMM, CNC, Laser, and metrology equipment. UNPARALLELED® Precision Granite is your trusted partner, offering not only a one-year warranty but also comprehensive industrial solutions. These include design assistance, improving designs, purchasing all necessary parts, inspecting and assembling rails and screws on precision granite machine bases, and more.

1 AAA Grade Industrial Nature Black Granite

UNPARALLELED® prefers granite material over marble for its superior qualities.

We carefully select premium natural granite materials to manufacture custom mechanical components tailored for high-end precision machinery. UNPARALLELED® granite materials are renowned for their stable physical characteristics and excellent properties. The density of our granite material is consistently higher than 3050kg/m³, surpassing that of marble, which generally has inferior physical properties in comparison.

2 More than 30 year experience Hand Lapping

Each precision granite component is subjected to meticulous hand lapping in order to meet the highest quality standards. At UNPARALLELED®, we utilize cutting-edge manufacturing and inspection technologies, complemented by a stringent Quality Control system, to ensure exceptional outcomes.

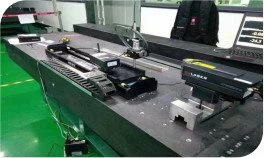

3 Professional and Authoritative Inspection and Calibration Reports

Our advanced measurement instruments encompass electric levels, laser interferometers, coordinate measuring machines (CMM), and additional technologies. Prior to shipment, we furnish a comprehensive inspection report for each granite component, thereby ensuring complete transparency and enhancing customer satisfaction.

|

BRAND |

UNPARALLELED® |

MATERIAL |

AAA Grade Industrial Nature Black Granite |

|

APPLICATION |

Metrology, CNC, Laser... |

DENSITY |

≈3100kg/m3 |

|

CONDITION |

NEW CUSTOM |

COLOR |

Pure Black |

|

ORIGIN |

JiNan, CHINA |

PRECISION |

1 μm or higher |

|

WARRANTY |

1 YEAR |

STANDARD |

DIN, GB, ASME,JIS... |

|

PACKAGING |

Custom Export Package |

CERTIFICATE |

ISO9001, ISO 45001, ISO 14001, CE... |

|

PAYMENT ITEM |

T/T, L/C... |

KEY WORD |

Granite Components, Precision Granite |

|

MATERIAL ORIGIN |

Jinan, China; India; South Afica |

TECHNICAL SUPPORT |

Inpsection& Calibration& Assembly |

|

PRICE |

EXW, FOB, CIF, DAP, CPT... |

SERVICE |

Design drawings |

Laser Interferometer

Electric Level

Roughness Meter

Vernier Caliper

Dial Gauge

Inductance Micrometer

Q:1.Who are we?

UNPARALLELED starts 1896, has the most advanced measuring and inspection equipment. We can manufacture a variety of ultra-high precision mechanical components for high-end machines.

Q:2.What material does UNPRALLELED® choose?

AAA Grade Nature Black Granite with density ≈3100kg/m3. UNPARALLELED® has found and inspected many kinds of granite material in all over the world.

Q:3.Is there an industry standard for surface plate accuracy?

Most manufacturers use DIN Standard, GB Standard, ASME B89.3.7-2013 or Federal Specification GGG-P-463c (Granite Surface Plates) as a basis for their specifications. You can access the DIN, GB, JIS, ASME spec or the GGG-P-463c from our Engineering department. You send email to: info@unparalleled-group.com

Q:4.What's The Granite Mechanical Components? & How To Choose Real Granite Not Marble?

Granite was used as a building and ornamental stone. With the continuous development of science and technology, stone application has been brought into a new field, and it has a wider application. Using high quality granite stone granite components machining and hand-made fine grinding, occupies an important position in the construction, decoration, decoration, metallurgy, machinery manufacturing, precision measuring tools, test equipment, finishing equipment etc...

Granite mechanical components are made of high quality black natural granite. UNPARALLELED searched many mines in the world, and found two kinds of black granite with stable physical properties and beautiful cut color --- Jinan Black Granite and Indian M10 Black granite. These two types of granite have stable physical properties and a density of 3030-3100kg/m3, which is a rare material for making precision mechanical components.

The material chosen by UNPARALLELED is granite not marble. At present, many manufacturers choose low-priced marble to deceive customers. Because customers do not understand the difference between granite and marble, and it is difficult to distinguish from the color of the stone, most customers still do not understand this product. Many customers may have questions, marble and granite are both stones, what is the difference? The difference can be big:

1. In terms of price, the price of granite is very expensive, and the price of marble is very cheap.

2. Granite is hard and marble is soft.

3. The physical properties of granite are stable and can maintain high precision; the physical properties of marble are not as good as granite, and the precision is easy to change.. .

In summary, granite is a good material for making precision mechanical components. Many manufacturers use cheap marble to pretend to be granite, thereby earning high profits. Many customers will ask how to choose granite instead of marble?

1. Ask the supplier to provide a stone analysis report.

2. Look for the UNPARALLELED brand.

3. The customer is required to provide corresponding stone photos, and the stone surface is not oiled or painted, and the color of the stone itself is retained. The color of the marble surface after manual grinding is different from that of the ground granite surface.

Q:5.Does UNPARALLELED offer Authoritative Inspection Report? ?

UNPARALLELED has the most advanced measuring devices.

UNPARALLELED all measuring equipment have the calibration report.

Q:6.We want to purchase one set this time, is this ok?

Of course. We can manufacture custom precision granite machine components according to your drawings. MOQ is 1 piece.

More information please contact: info@unparalleled-group.com